Arc Flash Studies and Equipment Labeling

What is it?

An arc flash describes the energy released from an electrical arcing fault. This type of fault is an explosion, one that generates a crushing shockwave at temperatures three and a half times that of the surface of the sun. As though that was not frightening enough, the blinding light, flying molten metal, and deafening sound waves add to the experience.

photo credit: https://pcxcorp.com/

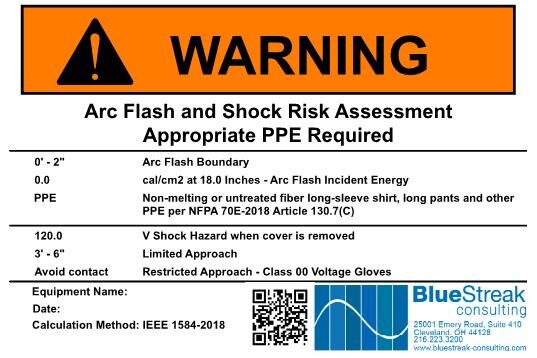

Arc flash studies are just one part of a comprehensive electrical safety program. The studies are done in order to create equipment warning labels that indicate a number of things, including the level of protective clothing and gear required in order to limit exposure below that of a second-degree burn (1.2 cal/cm2).

Is It Required?

In order to answer this question let’s walk through some of the governing laws, codes, and standards surrounding this issue.

OSHA: Occupational Safety and Health Administration

OSHA contains no specific requirement for arc flash labeling of electrical equipment. Pause. Pause. Pause... So there you have it, arc flash labels are not required, right? Well if you’re the type that only reads the first sentence of an email, finds the answer you were hoping to find, and then stops, I would implore you to break that habit (if just for today) and continue reading!

OSHA’s general duty clause (5)(a)(1) requires employers “to furnish to each of its employees a workplace that is free from recognized hazards that are likely to cause death or serious physical harm”. Additionally, Section 1910.333(a)(1)(v), Safeguards for personnel protection, requires employers to provide appropriate PPE "to protect each employee from shocks, burns, or other electrically related injuries while that employee is working . . . where dangerous electric heating or arcing might occur”. NFPA 70E is the industry-recognized standard for selecting appropriate PPE for arc flash protection.

OSHA recommends that employers consult consensus standards such as NFPA 70E to identify safety measures that can be used to comply with or supplement the requirements of OSHA's standards for preventing or protecting against arc flash hazards.

The following Standard Interpretation from OSHA dated 11/14/2006 is telling:

“Question: Does OSHA issue Section 5(a)(1) General Duty Clause violations to companies who do not follow the new NFPA 70E requirements?”

“Reply: A violation of the General Duty Clause, Section 5(a)(1) of the Act, exists if an employer has failed to furnish a workplace that is free from recognized hazards causing or likely to cause death or serious physical injury. The General Duty Clause is not used to enforce the provisions of consensus standards, although such standards are sometimes used as evidence of hazard recognition and the availability of feasible means of abatement”

The important takeaway is that employers are often leveed hefty fines for electrical workplace incidents and often cite NFPA 70E standards as supporting evidence in those citations.

NFPA 70E: Standard for Electrical Safety in the Workplace

NFPA 70E is the governing standard for electrical safety in the workplace. The standard by definition is not a code requirement, however, is commonly referenced within the governing law and in litigation regarding electrical safety.

The 2018 standard includes a myriad of requirements related to safe electrical work practices including labeling equipment where arc flashes may occur with the necessary information for worker safety. The standard offers two methods for the labeling and selection of PPE:

PPE Category Method

Incident Energy Analysis Method

The PPE Category method requires the maintenance personnel to reference a look-up table in the standard and depending on the task being performed and the type of equipment involved, the table will tell them what level of PPE is required. There are several drawbacks and limitations of the PPE Category Method, but at its worst, it could even recommend lower levels of PPE than would otherwise be required had a full study been performed.

The Incident Energy Analysis Method is considered to be a more reliable approach to determining the arc flash requirements. This method involves a detailed examination of the electrical systems serving the facility including:

A field investigation to gather detailed information on the equipment

Utility company coordination

Multiple iterations of calculations based on the IEEE 1584 Standard: Guide for Performing Arc-Flash Hazard Calculations

For complex systems, these calculations are typically performed with the assistance of expensive electrical modeling software. This method is used to create labels that provide the level of energy and appropriate PPE required for each piece of equipment included in the study. Although this method is more time-consuming and costly, it is considered to be a more accurate representation of the actual PPE requirements for your facility.

NFPA 70: National Electrical Code

As data continues to pour in regarding the dangers surrounding Arc Flash Incidents and the number of accidents in the workplace related to these events, the NEC has taken notice and begun to take steps to address this important issue.

The 2011 NEC first introduced a concept called Arc Energy Reduction (further expanded in both 2014 and 2017 versions) which addresses a requirement to reduce the amount of energy available at higher-rated pieces of equipment.

At this time the code does not require arc flash studies and labeling on all electrical equipment. NEC 110.16 Arc-Flash Hazard Warning only requires a general warning label to be provided to equipment indicating that there is some level of potential arc flash hazard. An Arc Flash Label is an acceptable means of satisfying the new requirement in the 2017 NEC 110.16(B), which requires a label with specific Arc Flash information be provided for service equipment greater than 1,200 Amps.

What Equipment is Required to be Labeled?

NFPA 70E requires labels for “equipment such as switchboards, panelboards, industrial control panels, meter socket enclosures, and motor control centers that are in other than dwelling units and that are likely to require examination, adjustment, servicing, or maintenance while energized.”

Example Arc Flash Label

If you have specific questions regarding exactly what equipment is required to be labeled at your facility consult with an engineer experienced in arc flash studies or trained electrical safety specialist.

Am I in Compliance?

NFPA 70E requires facilities to be reviewed whenever major modifications or renovations to the system are made or at periods not to exceed 5 years to account for changes in the electrical distribution system (including the utility company) that could affect the results.

If you are familiar with arc flash labeling and have had them done at your facilities in the past, you may be aware of the recently released update to the IEEE 1584 standard which significantly changed the way these calculations are performed and what equipment is required to be analyzed.

How Does the Update Affect Me?

The previous version of IEEE 1584 included an excerpt commonly known as the “125kVA Exemption” which permitted studies to exclude equipment at voltages under 240V fed by transformers 125kVA and smaller. The standard now reads as follows:

“Sustainable arcs are possible but less likely in 4-phase systems operating at 240V or less with an available fault current less than 2,000A”

The implication being that some equipment that formally fell under the 125kVA Exemption should now be included in the arc flash study and labeled accordingly.

Summary

Arc flash hazards are an extremely dangerous and often misunderstood component of your overall electrical safety program. Proper equipment labeling can help to eliminate confusion for employees and de-mystify the process of selecting the proper PPE. If you have any questions about arc flash labeling requirements at your facility or would like to receive a quote to provide an arc flash study and equipment labels please contact us using the form below.